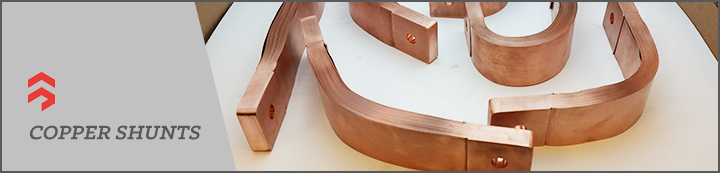

Laminated Copper Electrical Shunts

Storm Power engineers and fabricates flexible, laminated copper electrical shunts to offer OEM's an alternative to the rigid copper bus bar.

Storm custom manufacturers copper laminated flexible shunts with resistance values on par with standard copper bar. Our shunts cover the full range of ampacity needs, serving as an ideal solution for complex installations often with minimal space. Plus laminated copper shunts are just as effective as a rigid bar in preventing current imbalance and voltage loss.

Storm's laminated copper electrical shunts are made of several thin layers of laminated copper press-welded to create bonded ends. The hardened solid-like ends can be drilled or machined to create exact-size holes to enable the shunts to be specified and installed like any standard copper connector.

Laminated shunt applications include:

- power plants

- substations

- transformers

- large motors

- generators

- switchgear

Remember...

- Flexibility - As an alternative to solid copper or aluminum bus bars, Storm's laminated copper shunts are flexible and easy to install.

- Better Performance - Press or braised welding eliminates the use of solder or bolts that can create voltage loss or uneven current distribution.

- Longer Life - Press welded copper electrical shunts won't degrade as fast as soldered or bolted shunts offering up to a 1/3 longer lifespan.