Best Practices for HiPot Testing of Busbars

October 11, 2024 4:47 pm

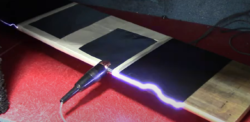

HiPot testing, short for high potential testing or high voltage testing, is a type of electrical safety test conducted to verify the insulation integrity and electrical strength of electrical components and systems. This test is crucial for busbars, which are conductive bars or strips used to distribute electricity within a system, often in industrial settings.

HiPot testing is performed to confirm that there is proper electrical isolation between conductors. For example, a HiPot test verifies that the multiple conductive layers within a laminated bus bar are sufficiently insulated from one another at a specified voltage.

The test runs a specific electrical voltage (AC or DC) through the conductor while a ground is created on the adjacent conductors to verify that there is no electrical path between them. Generally, the HiPot test is run at an exaggerated voltage level of 2X the operating voltage plus 1,000 volts to ensure safety and performance even in extreme scenarios.

This new applications note provides a deeper dive into Best Practices for HiPot Testing of Busbars.

Key types of HiPot testing include:

- DC HiPot Testing

- AC HiPot Testing

- Surge Testing

- Insulation Resistance Testing

- Partial Discharge Testing

- Visual and Physical Inspection

Read the Full Applications Note on HiPot Testing for Busbars

Uncategorized | by Storm Power Team

Comments are closed here.