Custom Copper Bus Bar Fabrication

Storm Power employs copper sourcing, CNC fabrication, laser, plating, and testing, and is one of a rare few to fabricate copper bus bar for numerous applications.

Silver Plated Copper Bus Bar

Storm's Expert Engineering and Design Support staff can also assist you in the fabrication of other custom busbar options such as:

- Laminated Bus Bar

- Busbar Insulations

- Inverter Bus Bar

- IGBT Bus Bar

- Power Distribution Bus Bar

- Backplane Bus Bar

- Circuit Breaker Bus Bar

- Multilayer Bus Bar

Custom Bus Bar

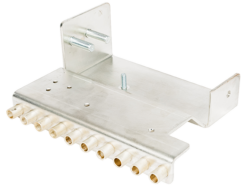

Storm Power custom manufactures bus bars for high-conductivity electrical power applications. Our bus bar is engineered to carry electrical power within cabinets and in external distribution assemblies. Due to the excellent conductivity of copper and aluminum, Storm's custom bus bars in copper and aluminum, are specified whenever an efficent and cost effective power connector is required.

The superior ampacity of electrical bus bars help achieve better thermal control in enclosed applications. Aluminum and Copper Bus Bar also improves the reliability of a power or electrical grounding connection by eliminating the need for a mechanical cable lug crimp.

Epoxy Insulated Bus Bar

Choose Storm fabricated bus bar to:

- Decrease system costs

- Eliminate wiring errors

- Improve reliability and thermal characteristics

- Lower inductance and impedance

- Increase interconnection method options

- Reduce capacitance

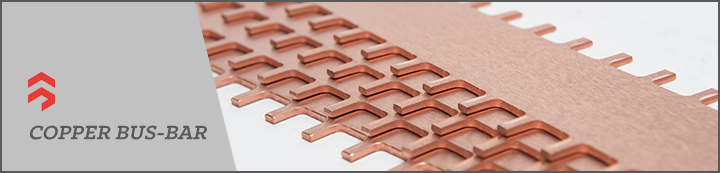

Copper Bus Bar Fabrication

When combined with Storm's Value Engineering, our full in-house CNC Capability saves even more time.

Virtually all of Storm's electrical bus bar business involves copper and a variety of core metalworking capabilities, all based on CNC technology. Storm's equipment includes presses, press breaks, water jet, laser and punching machines to produce materials, processes, and finished components engineered to meet standards required by AS9100D and ISO9001:2015, ASTM, UL, CSA, Bellcore, and other testing/standards bodies.

In addition, Storm's prototyping capability can put samples of bus bar connectors in your hands for evaluation in a matter of days.

Storm's In-House Electroplating Streamlines Busbar Production Even More by Eliminating the Time and Cost of Outsourcing.

- Bright and Matte Tin

- Lead

- Tin/Lead Alloys

- Nickel

- Silver

- Rack or Barrel Electroplating

- Strike Plating

- Electroless Nickel Plating

This capability is proven to reduce lead times critical to OEMs. Not only is internal electroplating more cost effective than outsourcing, plating in-house offers a green component to manufacturing by eliminating fuel consumption and pollution from transport from plant to plant.

Storm's In-House Testing Equipment also Eliminates Transport Costs.

Storm's quality inspection and testing equipment Includes:

- FARO Arm

- X-Ray

- Dielectric test (Hi-pot)

- Partial Discharge test

- Video Inspection (Keyence)

- Hardness test (Rockwell)

- Ultrasonic Thickness test

- Surface Roughness test