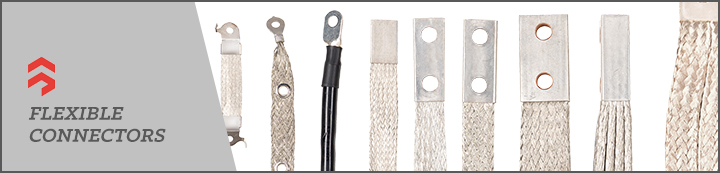

Flexible Braided Copper Connectors (Flexbraids)

Braided Copper Connector - Flexbraid - Jumper - Flexible Lead

Industrial or electrical engineers know that generators, turbines and transformers are the primary causes of vibration that affects performance at key distribution points in electrical power supplies, substations and industrial plants. Braided copper connectors provide a flexible electrical connection and dampen vibration.

Even with the addition of dampening pads and mounts, vibration still occurs throughout these power distribution networks, loosening lugs and other connectors attached to rigid electrical connectors like bus bars and grounding bars. While upkeep and synchronization can reduce the scale of vibration from generators and turbines, ultimately the remaining vibration takes its toll over time.

Loose connections result in a loss of performance, equipment failure and expansion from heat that dramatically increases the chance of fire.

Flexible braided copper connectors (a.k.a. flexbraid, flexible electric shunt, flexible lead, flexible jumper) solve high-voltage connectivity problems created by vibration from generators and transformers. When used as the initial connector from vibration-producing equipment to a power distribution network, flexbraids isolate the main electrical grounding bus work from the menace of vibration.

In addition to the positive aspects of flexbraid power shunts, the most advantageous feature of this versatile copper connector is evident in its name – flexibility.

Questions to ask in order to know exactly what specifications your flexbraid will require include...

- What is the current carrying capacity required?

- What size of ferrules (landing pads) will be needed on each end?

- Do you need round or flat braid material? Do you have a preference?

- Unplated or tin-plated copper braid material?

- How many braids will you need in the ferrule?

- Does your application require the ferrule itself to be electroplated?

- Do you know the hole size and pattern needed to bolt the braid?

- What circular mils of braids do you think you will need?

- Does the flexible braided connector need UL© certification?

→ For more information on these flexible connectors, a.k.a. flexbraids, visit our Specialized Capabilities page.

STORM POWER FLEXBRAID SPECIFICATION CHART

Mobile users swipe ↔ to see full table

| Flexbraid Series |

Braid AWG |

Maximum Ampacity |

Circular Mills |

Width | Ferrule Thickness |

# Braids | Braid Code |

|---|---|---|---|---|---|---|---|

| SC-BD | #1 | 190 | 96000 | 1.190" | .13" | 1 | 1 x 48 - 20-30 |

| SC-BE | 3/0 | 340 | 168000 | 1.250" | .21" | 1 | 2 x 24 - 35-30 |

| SC-BF | 4/0 | 375 | 230000 | 1.380" | .28" | 1 | 2 x 24 - 48-30 |

| SC-BG | 300 kcmil | 510 | 336000 | 1.630" | .36" | 1 | 2 x 48 - 35-30 |

| SC-B2D | 154 kcmil | 380 | 192000 | 1.190" | .23" | 2 | 1 x 48 - 20-30 |

| SC-B2E | 308 kcmil | 530 | 336000 | 1.250" | .35" | 2 | 2 x 24 - 35-30 |

| SC-B2F | 464 kcmil | 600 | 460800 | 1.380" | .375" | 2 | 2 x 24 - 48-30 |

| SC-B2G | 600 kcmil | 875 | 672000 | 1.630" | .50" | 2 | 2 x 48 - 35-30 |

| SC-B3D | 231 kcmil | 470 | 288000 | 1.190" | .27" | 3 | 1 x 48 - 35-30 |

| SC-B3E | 462 kcmil | 700 | 504000 | 1.250" | .28" | 3 | 2 x 48 - 48-30 |

| SC-B3F | 696 kcmil | 900 | 691200 | 1.380" | .52" | 3 | 2 x 24 - 48-30 |

| SC-B3G | 900 kcmil | 1000 | 1008000 | 1.630" | .59" | 3 | 2 x 48 - 35-30 |

| SC-B4D | 308 kcmil | 600 | 384000 | 1.190" | .41" | 4 | 1 x 48 - 20-30 |

| SC-B4E | 616 kcmil | 875 | 672000 | 1.250" | .39" | 4 | 2 x 24 - 35-30 |

| SC-B4F | 928 kcmil | 1000 | 921000 | 1.380" | .69" | 4 | 2 x 24 - 48-30 |

| SC-B4G | 1200 kcmil | 1200 | 1344000 | 1.630" | .94" | 4 | 2 x 48 - 35-30 |

CALL TO ORDER 1-800-394-4804

$200 line minimum on all orders

Storm stocks a wide range of flexbraid connectors. Not sure which ones? JUST ASK!

For a complete list of Storm's FlexBraids with pricing:

Braided Copper Grounding Straps

![]()

Don’t see it? We can make it! Sizes and combinations not shown and special drilling can be readily supplied upon request. Typical lead time for ground straps is 3 to 5 days, however, due to new extended lead times from our mills, many of our lead times have been extended. PLEASE CALL for current lead time.

Storm’s tinned copper-braid Grounding Straps and Jumpers are flexible grounding connectors intended to carry a charge to ground. These workhorse ground jumpers consist of tinned solid copper braid in a one-dimensional flex built to stand up to long term use. Storm fuses the ends of each ground strap to improve durability and tensile strength with low-RoHS solder to prevent fraying.

Please note: Storm does not recommend Braided Copper Grounding Straps for continuous current-carrying applications.

Uses include:

- Electrical enclosures – where flexible connectors are needed to take charge to ground

- Electrical panel doors – or switchgear doors with inadequate connections in the hinges

- Security fences around substations and utilities

- Fence and gate jumpers

- Generators and transformers – for a continuous ground accommodating motion and vibration

- Power and utility boards

- Oil, gas and flammable liquid tanks – especially around lids, caps and spigots

- Other equipment used in static grounding

CALL FOR INFO 1-800-394-4804

| Braid AWG |

Maximum Ampacity |

Circular Mil Area |

Size: Thickness & Width | Braid ID No. |

| 12 | 40 | 7200 | .030" Thick x .375" Wide | JXB-48636-T |

| 11 | 53 | 9600 | .032" Thick x .500" Wide | JXB-48836-T |

| 8 | 70 | 18000 | .063" Thick x .625" Wide | JXB-481536-T |

| 6 | 93 | 26400 | .075" Thick x .500" Wide | JXB-241130-T |

| 5 | 110 | 40800 | .080" Thick x .700" Wide | JXB-483436-T |

| 4 | 130 | 48000 | .065" Thick x 1.000" Wide | JXB-484036-T |

| 3 | 135 | 56900 | .063" Thick x 1.375" Wide | JXB-4812040-T |

| 1 | 190 | 80600 | .125" Thick x 1.000" Wide | JXB-243230-T |

| 1 | 200 | 86400 | .090" Thick x 1.187" Wide | JXB-481830-T |

| 1 | 230 | 100800 | .080" Thick x 1.620" Wide | JXB-488436-T |

| 1/0 | 235 | 105600 | .125" Thick x 1.500" Wide | JXB-482230T-1 |

| 1/0 | 240 | 110400 | .093" Thick x 1.750" Wide | JXB-482330-T |

| 2/0 | 290 | 153600 | .187" Thick x 1.25" Wide | JXB-2-243230-T |

| 2/0 | 290 | 153600 | .250" Thick x 1.500" Wide | JXB-2-483230-T |

| 3/0 | 320 | 168000 | .125" Thick x 1.620" Wide | JXB-483530-T |

| 3/0 | 320 | 168000 | .125" Thick x 2.500" Wide | JXB-483530T-1 |

| 4/0 | 211200 | .187" Thick x 1.380" Wide | JXB-2-244430-T | |

| 3/0 | 360 | 168000 | .300" Thick x 1.250" Wide | JXB-2-243530-T |

| 4/0 | 390 | 225600 | .150" Thick x 2.750" Wide | JXB-484730-T |

| 300 mcm | 465 | 307200 | .250" Thick x 1.500" Wide | JXB-2-483230-T |

| 300 mcm | 510 | 336000 | .312" Thick x 1.500" Wide | JXB-2-483530-T |