Bus Bar Engineering Resources

FREE Downloads:

Product Guides, Ampacity Charts and White papers

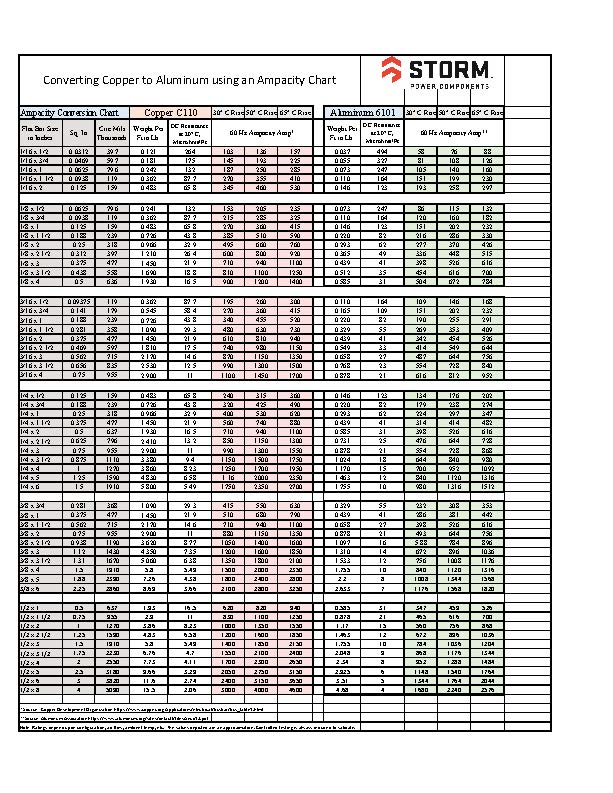

Welcome to Storm Power’s Bus Bar Resources. Listed below are bus bar design specifications on Insulation, Epoxy Powder Coating, Multilayer Laminated Conductors, Copper and Aluminum Ampacity Tables, Copper vs. Aluminum Performance Comparison, Flexible Bus Conductors, to name just a few of the subjects covered. Please don’t hesitate to give us a call at 800-394-4804 if you need assistance with an engineering question not covered in the pdf documents below.

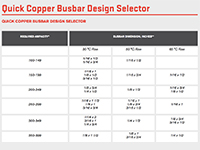

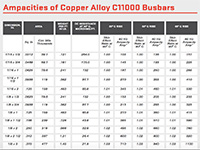

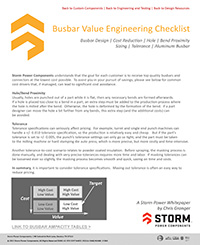

4. BUS BAR PROFILE vs. CURRENT DENSITY SIZING GUIDE

The following chart shows the impact of changes in bus bar size to the overall current density of the conductor.

| Dimension, In. | Area | Weight Per Ft in Lbs |

Amperage | DC Resistance at 20° C |

30° C Rise | 50° C Rise | 65° C Rise | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sq. In | Circ Mils Thousands |

Amps/ Circ Mils |

Amps Per Sq. Ft. |

Microhms Per Sq. Ft. |

Skin Effect Ratio at 90° C |

60 Hz Ampacity Amp* |

Skin Effect Ratio at 90° C |

60 Hz Ampacity Amp* |

Skin Effect Ratio at 90° C |

60 Hz Ampacity Amp* |

||

| 1/16 x 1/2 | .0312 | 39.7 | .121 | 385 | 3209 | 264.0 | 1.00 | 103 | 1.00 | 136 | 1.00 | 157 |

| 1/16 x 2 | .125 | 159 | .483 | 460 | 2760 | 65.8 | 1.01 | 345 | 1.01 | 460 | 1.01 | 530 |

| 1/8 x 1 | .125 | 159 | .483 | 589 | 2160 | 65.8 | 1.01 | 270 | 1.01 | 360 | 1.01 | 415 |

| 1/8 x 3 1/2 | .438 | 558 | 1.69 | 688 | 1849 | 18.8 | 1.04 | 810 | 1.03 | 1100 | 1.03 | 1250 |

| 3/16 x 1 | .188 | 239 | .726 | 702 | 1808 | 43.8 | 1.01 | 340 | 1.01 | 455 | 1.01 | 520 |

| 3/16 x 3 | .562 | 715 | 2.17 | 821 | 1548 | 14.6 | 1.05 | 870 | 1.05 | 1150 | 1.04 | 1350 |

| 1/4 x 3/4 | .188 | 239 | .726 | 746 | 1702 | 43.8 | 1.01 | 320 | 1.01 | 425 | 1.01 | 490 |

| 1/4 x 3 | .750 | 955 | 2.90 | 965 | 1320 | 11.0 | 1.08 | 990 | 1.08 | 1300 | 1.07 | 1550 |

| 3/8 x 2 1/2 | .938 | 1190 | 3.62 | 1133 | 1119 | 8.77 | 1.12 | 1050 | 1.10 | 1400 | 1.09 | 1600 |

| 1/2 x 1 1/2 | .750 | 955 | 2.90 | 1150 | 1107 | 11.0 | 1.08 | 830 | 1.08 | 1100 | 1.07 | 1250 |

| 1/2 x 4 | 2.00 | 2550 | 7.73 | 1500 | 850 | 4.11 | 1.26 | 1700 | 1.25 | 2300 | 1.24 | 2650 |

| 1/2 x 10 | 5.00 | 4770 | 14.5 | 1998 | 640 | 1.65 | 1.48 | 3250 | 1.46 | 4800 | 1.44 | 3750 |

| 3/4 x 10 | 7.50 | 9550 | 7.73 | 2274 | 560 | 1.10 | 1.67 | 5600 | 1.64 | 5600 | 1.62 | 6500 |