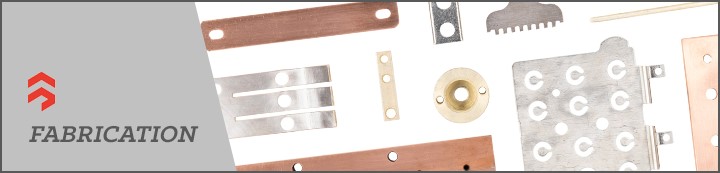

Electrical Bus bar Fabrication in

Copper, Aluminum, or Brass

The skilled fabricators at Storm Power Components have the expertise to take on complex electrical component fabrication. Whenever the tightest tolerance is needed on copper and aluminum parts, Storm Power is the right choice.

When Storm's Responsive Manufacturing™ is combined with Value Engineering, the result will shorten lead time while increasing the value of the method used to fabricate custom electrical components, such as custom bus bar made of copper or aluminum.

OEM components move through one or more of the following process paths during fabrication:

Cold Cutting; high and low volume

Using an automated CNC Cold Saw, we can produce precise length and mirror-like finish on custom fabricated components. Because we’re laser focused on production efficiency, we have versatile equipment to cut copper or aluminum sheet, plate and bar, to produce high and low volume runs, as well as prototype quantities.

Copper and Aluminum Forming & Bending;

conventional, offset & side

This is a secondary step in the electrical component fabricating process and is performed after the part has been cut to length and punched or milled. During this process, the part is bent or formed to the specifications of the print. To reduce lead times, Storm’s forming and bending capability includes the design and manufacturing of offset and special forming tools.

Copper Stamping; coil line process and in-house die fabrication

This method of producing copper and aluminum parts is performed using high speed production presses. The range of material Storm processes is .062” to .187” copper and aluminum bar stock or coil. The production and tolerance on this method of fabrication varies depending on the tooling and material employed. Read more about our in-house Die Fabrication capability.

Machine Punching

Storm offers multiple punching equipment tools to perform different geometries of holes, including round, square, oblongs, or special features. Available hole sizes and shapes vary with material thickness. Our punching and precision cutting machines have various automations, and are CAD-CAM programmable to produce custom copper electrical connectors, all from the same long sheet or conveyor-fed copper bar.

-

- CNC automated punching machines have multiple tool holders and the tonnage to punch up to .500" thick copper bar and plate. This punching cell is best suited for high to mid volume production runs.

- Turret-style operations perform punching and cutting on the perimeter of the copper part. Using dynamic nesting software for maximum material utilization, this is the primary method of producing parts with odd shapes, tabs, forms or fingers. Generally, the thickness of the copper is .250" and less.

- CNC single stroke; this punching press is an efficient means best suited for low volume production runs.

Precision CNC Machining; turning and milling with multi-axis capability

This method of fabricating out of copper or aluminum, also known as milling, has the greatest versatility and can produce an almost endless array of custom copper fabrications. Moreover, tolerances as close as .001" are achieved with this equipment. While this is a relatively higher cost method of production due to set-up, tooling costs, and run-time, Storm’s expertise in developing unique fixturing can minimize these costs and provide competitive pricing.

Precision Machining; turning and milling with Swiss–style screw machine

Traditional screw machines are ideal for long production runs of turned parts, but often have very high set up costs, requiring large MOQs for efficiency. Swiss-style lathe machines greatly reduce these costs, and can be efficient for shorter production runs.

Press/Fused Welding

This manufacturing technique heats and squeezes individual copper laminates into a nearly solid copper bar state. Using copper sheets in varying sizes from 0.003" to 0.045" thickness positioned between heated graphite blocks, the process uses tonnage to press sheets together, creating a tight bond. Press-welded connectors are a great choice in non-stationary applications where minimal voltage loss and flexibility are absolutely necessary.

Brazing; high and low heat transfer

If cost is a concern when adding copper standoffs, brazing should be your method of choice. Typically performed just before electroplating, brazing adds a filler material to create a super strength conductivity bond between copper pieces. Because this method involves the proper transfer of heat (between 400 -1400 degrees), Storm employs skilled professionals to braze warp-free components to precise specifications. Our customers have learned to trust Storm to perform a variety of brazing techniques, using materials ranging from fluxes to highly conductive silver and softer solders.

Copper and Aluminum Abrasive Cutting

This method of cutting uses high water pressure and abrasive materials focused into a CNC controlled cutting stream to slice copper or aluminum. Commonly referred to as water jet cutting, this process offers a smooth cut; free of nibble marks and burrs, on aluminum and copper parts. This method is best suited for slicing geometries that cannot be achieved with conventional punching, or when a higher level of finish is desired.

Copper reacts drastically to tonnage stress, therefore, the water jet or abrasive cutting brings the advantage of gentle erosion of material to form the complex geometry, with minimal distortion, and tighter tolerances.